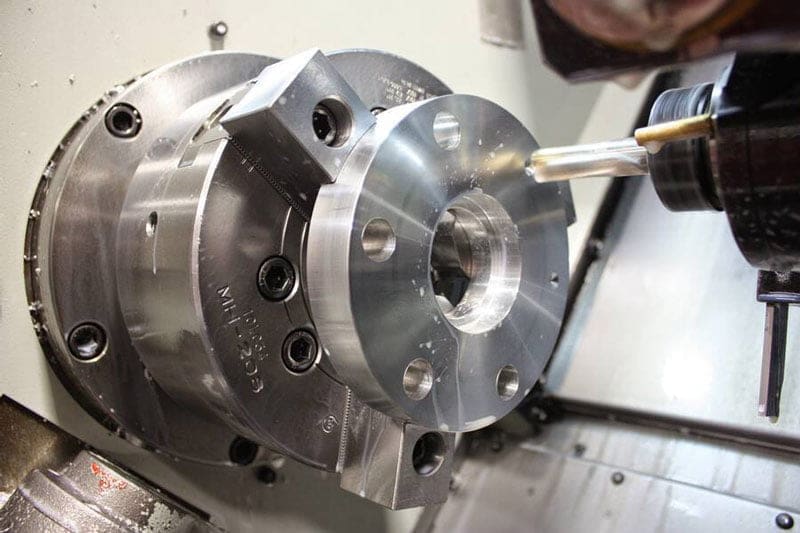

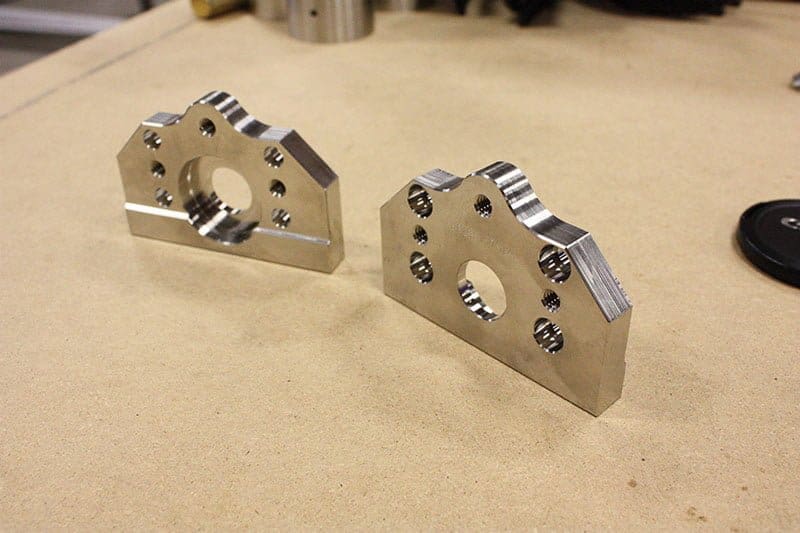

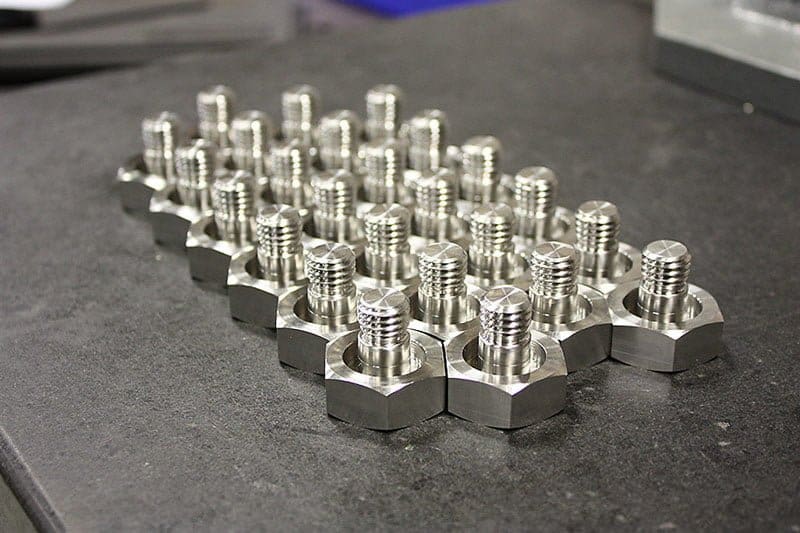

FTS harnesses the prowess of cutting-edge CAM technology, complemented by CNC and traditional machining methods. Our commitment to innovative machining services and techniques has carved a niche for us, especially in the precision crafting of stainless steel and aluminum products.

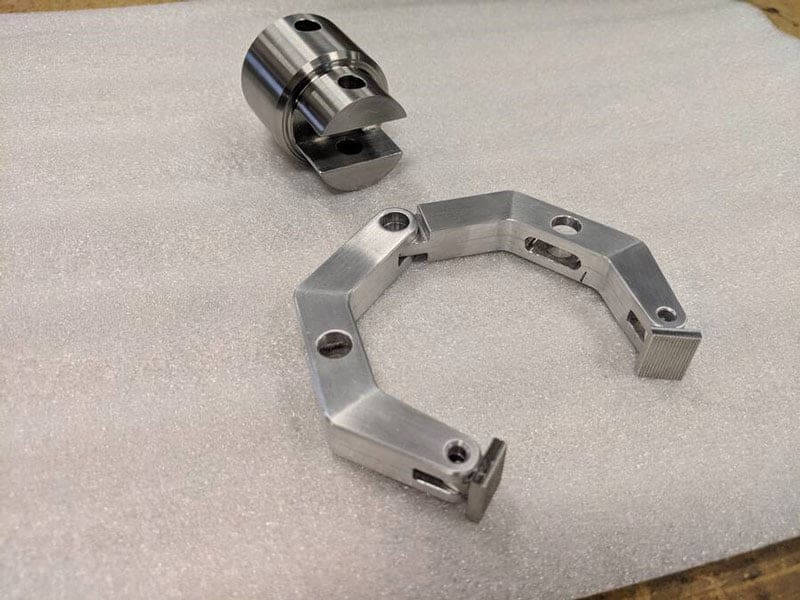

With the capability to process a wide array of metals and non-metallic materials confidently, we pride ourselves as a custom shop adept in delivering one-off units, specialized fixtures, prototypes, and small to medium production runs.

Every machining operation we undertake is dedicated to crafting components tailored to specific customer orders, seamlessly aligning with and enhancing our fabrication and millwrighting offerings.

CNC Milling

– 76” x 31.5” table

– 40” x 20” table, 4th axis with trunnion fixturing capabilities.

CNC Turning

– 8” chuck, 2.5” thru-bore, C Axis with live tooling, programmable tailstock.

– 12” chuck, 4.02” thru-bore, C Axis with live tooling, programmable tailstock.

Boring Mill

– 70.86” x 49.2” x 49.2” travel with 24.8” W-Axis Travel (Quill).

Manual Machining

– Engine Lathes

– Vertical Mill,

– Radial Arm Drill

– Industrial Drill Press

– Horizontal Band Saw.

In the intricate world of machining, FTS stands distinct. We believe in merging the best of both worlds – the advanced with the traditional, the new-age with the time-tested. Our approach is rooted in leveraging top-tier CAM technology while paying homage to established CNC and conventional methodologies. It’s this synthesis, this thoughtful integration, that positions us at the forefront of the industry, allowing us to deliver unmatched quality and precision tailored to each unique project.

At FTS, we blend cutting-edge CAM technology with the tried-and-true methods of CNC and conventional machining. This harmonious integration is our secret to delivering components that epitomize accuracy and precision.

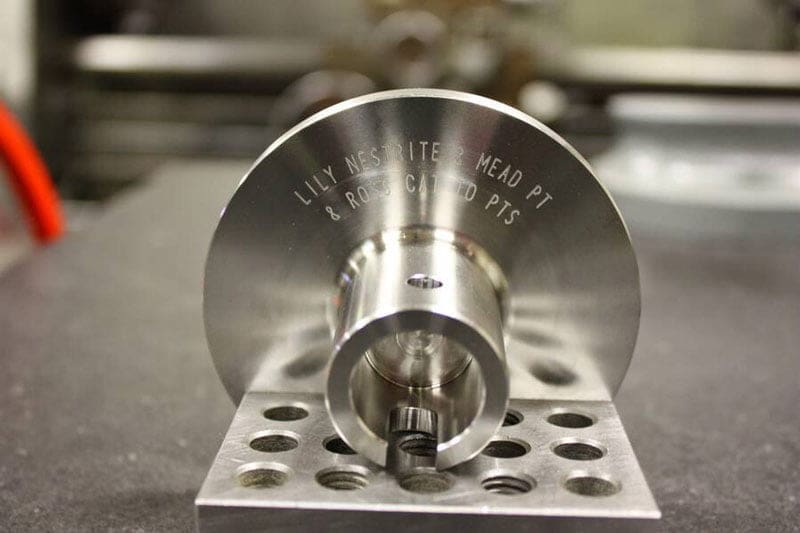

Our relentless pursuit of innovative machining techniques is evident. It’s this commitment that’s garnered us a standout reputation, especially in crafting top-tier stainless steel and aluminum products. Beyond that, our expertise extends to efficiently processing a diverse range of metals and non-metallic materials.

In the realm of machining, one size rarely fits all. At FTS, we recognize the distinct requirements of each project and client. Our approach emphasizes crafting bespoke solutions, ensuring that every piece we produce aligns perfectly with your vision and needs.

At FTS, we understand the importance of precision and individuality. Whether it’s a single, distinctive piece, a prototype, or a part of a broader production batch, our dedicated custom shop ensures that each product is crafted with a meticulous eye and tailored precisely to your needs.

Beyond the standalone machining tasks, our operations extend to form the backbone of many FTS services. We’re proud to be the driving force behind our fabrication and millwrighting divisions, ensuring seamless integration and unparalleled quality across all FTS projects.

Stepping into the dynamic world of machining, it’s essential to align with a partner that understands the nuances and intricacies of the industry. FTS stands out for a myriad of reasons.

With a legacy built on innovation and precision, our progressive techniques in machining have placed us at the forefront, especially when it comes to crafting impeccable stainless steel, aluminum, and various other materials.

Our commitment doesn’t end at production. At FTS, we pride ourselves on offering holistic solutions. Our custom shop model is versatile, adapting to diverse client requirements, be it for individual units or for more extensive small to medium production runs.

At Flamboro Technical Services, we believe that the true essence of success lies in collaboration. Beyond mere transactions, we prioritize building and sustaining healthy relationships with our clients.

Every partnership we cultivate is a testament to our dedication, mutual respect, shared goals and trust. It’s not just about providing services; it’s about understanding the intricate nuances of each client’s vision and challenges. Through these deep-rooted collaborations, we find ourselves better equipped and inspired to craft tailor-made solutions that cater to the most unique applications and specifications.

“FTS consistently delivers a high quality product while maintaining the flexibility for a quick response required by our business.”

Colin J | Engineering Manager

FTS specializes in machining stainless steel and aluminum. However, we also confidently process a variety of other metals and non-metallic materials to meet diverse client needs.

Absolutely! Our custom shop approach allows us to cater to unique, one-off pieces, fixtures, and prototypes, as well as small-to-medium production runs.

FTS utilizes state-of-the-art CAM technology and integrates both CNC and conventional machining processes. Our commitment to progressive techniques guarantees accuracy and top-tier quality in every component we produce.

Our machining operations play a pivotal role in supporting other facets of FTS, including the fabrication and millwrighting services. We provide components as per customer orders and ensure a cohesive integration with broader projects.

FTS stands out for its reputation for excellence, progressive approach, and commitment to end-to-end custom solutions. Our deep industry experience and the ability to deliver tailored solutions make us a preferred choice for diverse machining needs.